What Does Vericut CNC Machine Connect Do?

- Verify Tool and Work Offsets on the CNC

- Verify the correct CNC Program has been loaded

- Drive Vericut with live CNC data

- Replay actual CNC activity in Vericut from recorded machine data

- Continue reading for more information about how to get the best digital twins in manufacturing

How Manufacturers Can Get The Most Accurate Digital Twins

Manufacturers should strive to create the most accurate digital twins possible because precision in digital replication directly impacts efficiency, quality, and decision-making on the shop floor. An accurate digital twin mirrors the real-time performance, behavior, and condition of physical equipment, allowing manufacturers to simulate processes, identify inefficiencies, predict maintenance needs, and avoid costly downtime. It also enables better collaboration across teams, improves the accuracy of quoting and scheduling, and supports continuous improvement initiatives. Simply put, the more accurate the digital twin, the more powerful and actionable the insights, leading to smarter operations and stronger bottom-line results.

Get those results with Vericut CNC Machine Connect, the integration that gives users the ability to connect Vericut directly to CNC machines through DataXchange to utilize real-time data from the shop floor. Take your CNC simulation to the next level by creating the most accurate digital twin of your machines possible and establishing a more streamlined manufacturing process. Vericut CNC Machine Connect has three components, Precheck, CNC Machine Monitoring–Live Streaming and Postcheck.

Take Vericut Digital Twins To The Next Level With Vericut Cnc Machine Connect

Scytec has partnered with Vericut to integrate the DataXchange machine monitoring system via the CNC Machine Connect module. This allows Vericut to connect directly to CNC machines using real-time shop floor data, enabling highly accurate digital twins and a more efficient manufacturing process. CNC Machine Connect includes Precheck, Live Monitoring, and Postcheck.

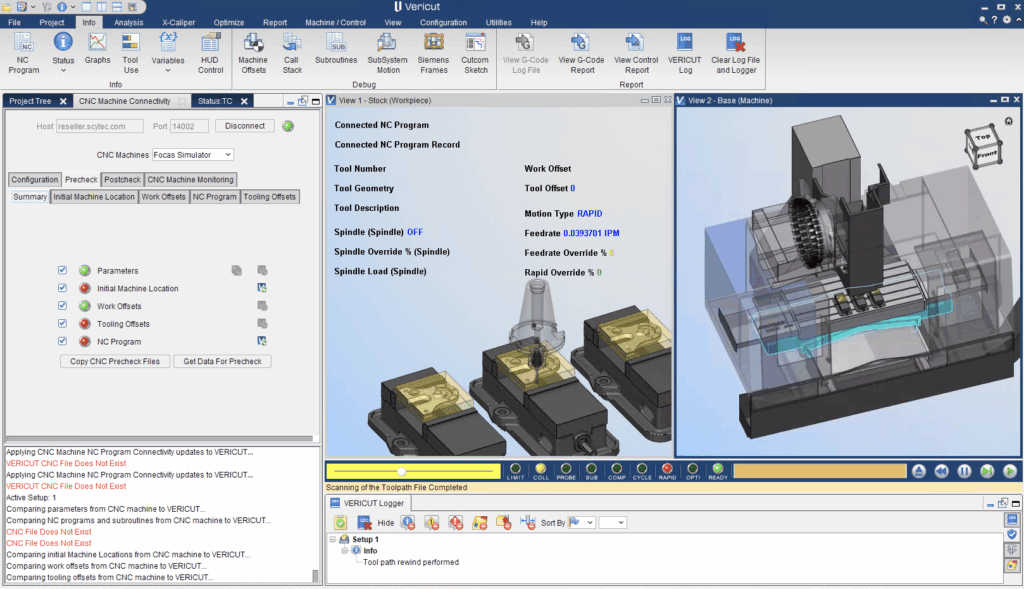

With Vericut’s Precheck, operators can make sure all the machine setup matches what was simulated in Vericut. Notifications alert individuals when a Precheck is run and what the results are.

On the left, you can see a Precheck has run with tool offsets, NC program and the machine location all failing, alerting the user to re-run the simulation after fixing the issues.

Watch The Videos Below To Find Out More About Vericut: CNC Machine Connect!

Vericut: CNC Machine Connect-Precheck

Vericut: CNC Machine Monitoring and Postcheck- Live Stream and Replay Your Production

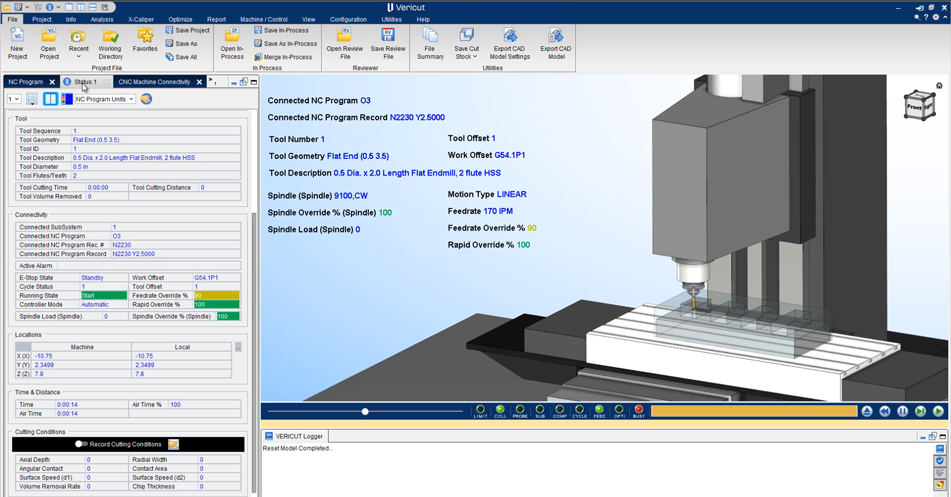

Vericut CNC Machine Monitoring– Live Streaming allows users to stream and track real-time machine activity directly in Vericut, even when you’re away from the shop floor. Postcheck gives you powerful insight by replaying archived machine data in the simulation to analyze performance and troubleshoot issues with specific parts with ease.

Vericut’s live-streaming feature in CNC Machine Connect enables the CNC machine to display how the real machine is behaving by viewing the active NC program and NC block record, cutting tool and offset values, feedrate override and spindle loads, as well as the E-Stop state and alarms.

Leverage the power of Postcheck to quickly access and replay past machining data in Vericut. Postcheck retrieves data from when the part was machined and replays this data in Vericut to observe how the machine actually ran the part. Use Postcheck to unearth a problem during the machining process, as well as analyzed data to proactively improve your machining process.

Ready To See CNC Machine Connect? Schedule A Demo Below!

Watch This Webinar For More Info On CNC Machine Connect With Vericut Specialists

Want To Know More About CNC Machine Connectivity?

Watch this in depth exploratory video from Vericut Director of Product Management, Gene Granata about the value that real-time data from CNC machines provides manufacturers looking to improve.

Why Now Is The Time To Connect Your CNC Machines and Begin Your Shop Floor’s Digital Transformation

Manufacturing is changing fast, and digital transformation has become essential, not optional. If your CNC equipment is still operating in isolation, relying on paper logs or manual operator updates, you’re missing out on efficiencies and opportunities that your competitors are already capturing.

The Cost of Unconnected Equipment

CNC machinery drives production. But without real-time visibility into performance, you’re left guessing about what’s really happening on the floor. When you don’t have accurate data, it becomes nearly impossible to:

- Identify the causes of downtime

- Reduce scrap and rework

- Track performance against goals

- Improve machine and labor utilization

- Uncover bottlenecks and wasted time

- Celebrate wins backed by proof

This lack of insight results in slower decisions, unnecessary costs, and production friction. And many manufacturers stay stuck simply because change feels intimidating — or because they’re waiting for the “right time.”

The truth: there’s no better time than now to modernize and prepare for growth cycles ahead. You already have what you need to start.

Digital transformation doesn’t require a massive overhaul. The smartest first step is connecting the equipment you already rely on daily.

From advanced 5-axis machines to older 3-axis models with controls from Fanuc, Okuma, Siemens, Heidenhain, Mitsubishi, and others, most CNCs can be digitally enabled. With machine monitoring platforms such as Scytec DataXchange, shops can instantly unlock:

- Real-time and historical machine data

- Automated OEE and downtime tracking

- Feed rate and override visibility

- ERP and Vericut software integrations

- Shift, operator, and machine-level analytics

- Alerts for stoppages or abnormalities

Manufacturers using DataXchange machine monitoring frequently see 10–30% OEE gains within days or weeks, turning a small initial investment into major operational wins.

Why Acting Now Matters

Manufacturers are facing more uncertainty than ever; labor shortages, supply delays, shifting customer demands, and reshoring pressures. Data-driven decision-making is no longer a luxury; it’s the only way to remain agile and profitable.

Despite progress, outdated perceptions about manufacturing persist. Many workers — especially Gen Z — view plants as technologically behind, making hiring harder at a time when the workforce is already strained. Employees are also spending hours each week on “gray work”: manual tasks needed just to gather, enter, and interpret information. Connecting CNC machines is a manageable, high-impact way to launch your digital transformation. It supports:

- Lean manufacturing

- Continuous improvement

- Standardization and accountability

- Future capabilities like predictive maintenance

By building a connected foundation now, you position your operations to scale, adapt, and stay competitive, no matter what comes next.